Composite industry cleaners

A lot of specialty products

Cleaners for the composite industry

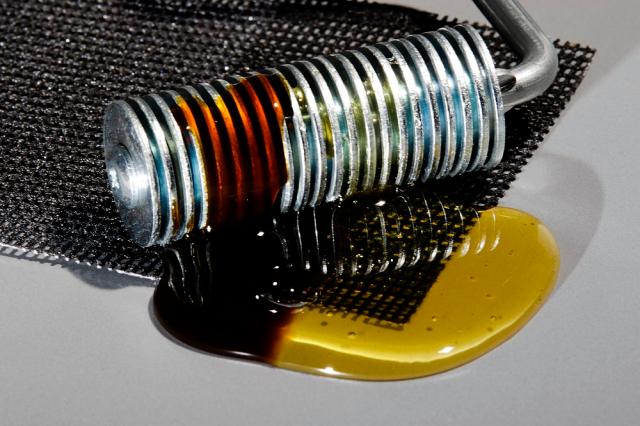

Cleaners for the composite industry is a diverse market with a lot of specialty products applied for cleaning of unsaturated polyester resins, epoxy resins, and polyurethane foams & resins. ESTI CHEM offers alternatives to traditional solvents under the RESIN CLEANER brand name.

The RESIN CLEANER products are applied for mold, system & tool cleaning purposes with an improved EH&S profile compared with the traditional solvents::

-

-

- Lower CLP labelling

- Higher flash point

- Lower VOC content

- Lower consumption due to lower evaporation loss.

-

By using RESIN CLEANERs as alternatives to acetone, MEK, NEP and limonene, a significant improvement of the working environment can be achieved.

Ask ESTI CHEM for advice, when you want to start a solvent replacement project to improve the working environment and the process safety in your company.

Cleaning agents for unsaturated polyester resins

Unsaturated polyester resins (UPRs) are widely used in the composite industry due to their excellent mechanical properties and versatility.

However, during the manufacturing process, UPRs can leave behind residues and contaminants that need to be effectively cleaned to ensure high-quality composite products.

Cleaning agents play a crucial role in this regard. The cleaning process for UPRs involves several steps: First, the surface is inspected to identify the type and extent of contamination. Then, the appropriate cleaning agent is wiped or sprayed on the surface using a clean cloth or a brush.

Stubborn or heavy contaminants may require agitation or soaking. Solvent-based cleaners are commonly used due to their ability to dissolve and remove various types of contaminants effectively. Common solvents used include acetone, and methyl ethyl ketone (MEK). These solvents have excellent solvency power, but they are highly flammable and pose a risk for the operators by inhalation.

RESIN CLEANER A has positioned itself as a valuable alternative to acetone in the UPR industry. The flash point is >100ͦC, the evaporation loss in minimal and the product has no CLP labelling.

Cleaning Agents for Epoxy Resins

Epoxy resins are widely used in the composite industry due to their exceptional adhesive properties, high strength, and chemical resistance

However, epoxy resins can be challenging to clean due to their strong bonding characteristics.

The effective use of cleaning agents is vital in maintaining the quality of epoxy resin composites. Cleaning epoxy resins involves a combination of techniques. For uncured or partially cured epoxy, solvent-based cleaners are often used. The epoxy surface is soaked or sprayed with the cleaning agent and then scrubbed or agitated to break down the resin.

For fully cured epoxy, water-based cleaners are preferred. The surface is typically soaked or sprayed with the cleaner, followed by scrubbing with a soft brush or sponge. In some cases, mechanical methods such as blasting or sanding may be required for stubborn contaminants.

Solvent-based cleaning agents are commonly used for cleaning epoxy resins. Acetone, MEK, gamma-butyro lactone (GBL), NMP and other strong solvents are effective in dissolving and removing uncured or partially cured epoxy resins. However, such solvents pose several risks for the operators, the environment, and process safety.

RESIN CLEANER EP2 and RESIN CLEANER EP40 are extremely efficient cleaning agents for epoxy resins with a flash point >60ͦC, they have less CLP labelling than many, traditional strong solvents, and they have a much lower evaporation loss.

Cleaning agents for polyurethane foam & resins

Polyurethane foam is widely used in the composite industry for its lightweight, durable, and insulating properties

When manufacturing polyurethane foam products, molds are used to shape and form the foam.

After the foam has cured and solidified, it is necessary to clean the molds effectively to maintain product quality and ensure smooth production processes. Cleaning polyurethane foam from molds can be a challenging task due to the unique properties of the foam. Polyurethane foam is known for its high expansion and adherence to surfaces, making it difficult to remove from molds.

Several types of cleaning agents are commonly used for cleaning polyurethane foam from molds. These include solvent-based cleaners, and mechanical cleaning methods. Solvents such as NMP, NEP, DMF, and gamma-butyro lactone (GBL) are often used to dissolve and remove uncured or partially cured polyurethane foam. However, also in this case the solvents pose several risks for the operators, the environment, and process safety. Similar solvents are applied for cleaning of polyurethan resins such as polyurethan adhesives.

RESIN CLEANER PU 21 and RESIN CLEANER PU30 are extremely efficient cleaning agents for polyurethane foam with a flash point >60ͦC, they have less CLP labelling the traditionally used solvents, and they have lower evaporation loss.

For non-cured or semi-cured polyurethane adhesives (for example for use as flushing agents for pray nozzles), RESIN CLEANER A is successfully applied as flushing agent.